Mixed-in-Place and Cutter-Soil-Mixing

Why haul away soil and bring in new materials when the soil can be used for construction? The Mixed-in-Place (MIP)- and Cutter-Soil-Mixing (CSM)-methods developed by the BAUER Group avoid the need for labour-intensive transport coordination, cut costs, reduce emissions and so relieve the strain on residents in the neighbourhood. Both methods offer efficient, cost-effective and environmentally friendly alternatives in the appropriate ground.

Types of Construction Method

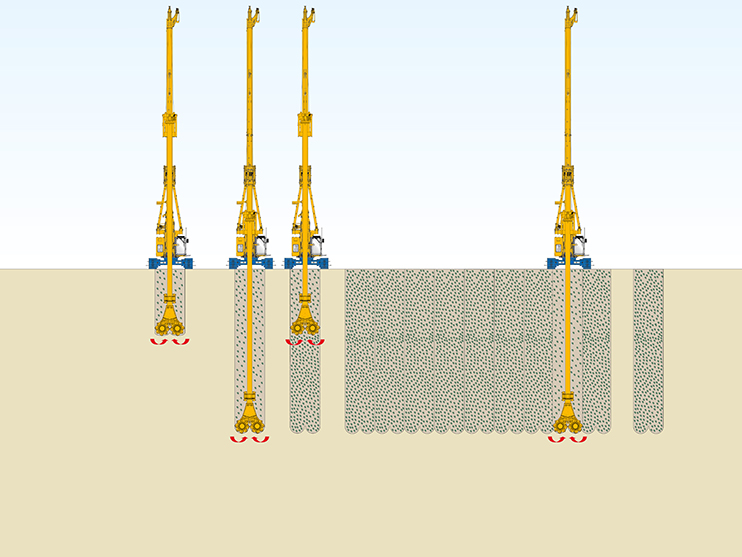

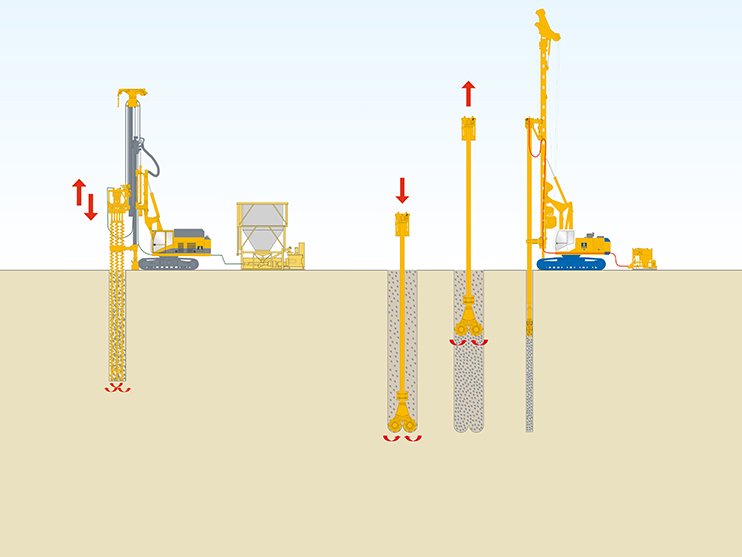

The Mixed-in-Place (MIP) method is particularly suitable in non-cohesive soils for the construction of cut-off walls as groundwater or pollution control, for remediating dykes and dams, or for the installation of structural retaining structures to secure terraces in the ground and excavation pits. In the MIP method, the surrounding soil is broken up with a single or triple auger, turned over and the pores filled with binder suspension. The individual units are combined to form walls by the step back method. In this, it is the size of the auger(s) that ultimately dictates the unit size. Reinforcing elements can be installed in the fresh MIP mix for structural strengthening.

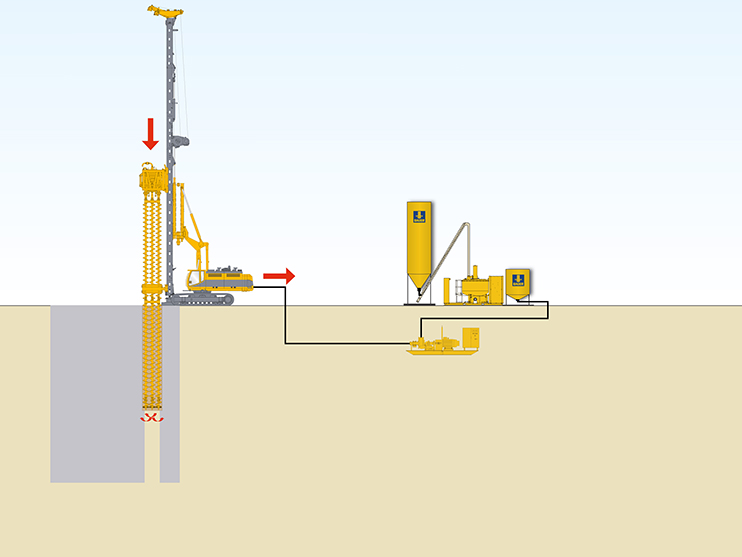

The Cutter-Soil-Mixing (CSM) method combines features of the diaphragm wall technique and the MIP method, as well as offering some additional benefits: the use of modified, high-performance cutters means soil mixing is possible even at very great depths and in very densely packed soils. The method also enables even greater wall thicknesses and higher levels of reinforcement to be attained. Accordingly, in addition to the applications described for the MIP method, the CSM method is suitable in particular for securing very deep excavation pits or for reinforcing high dams and dykes.